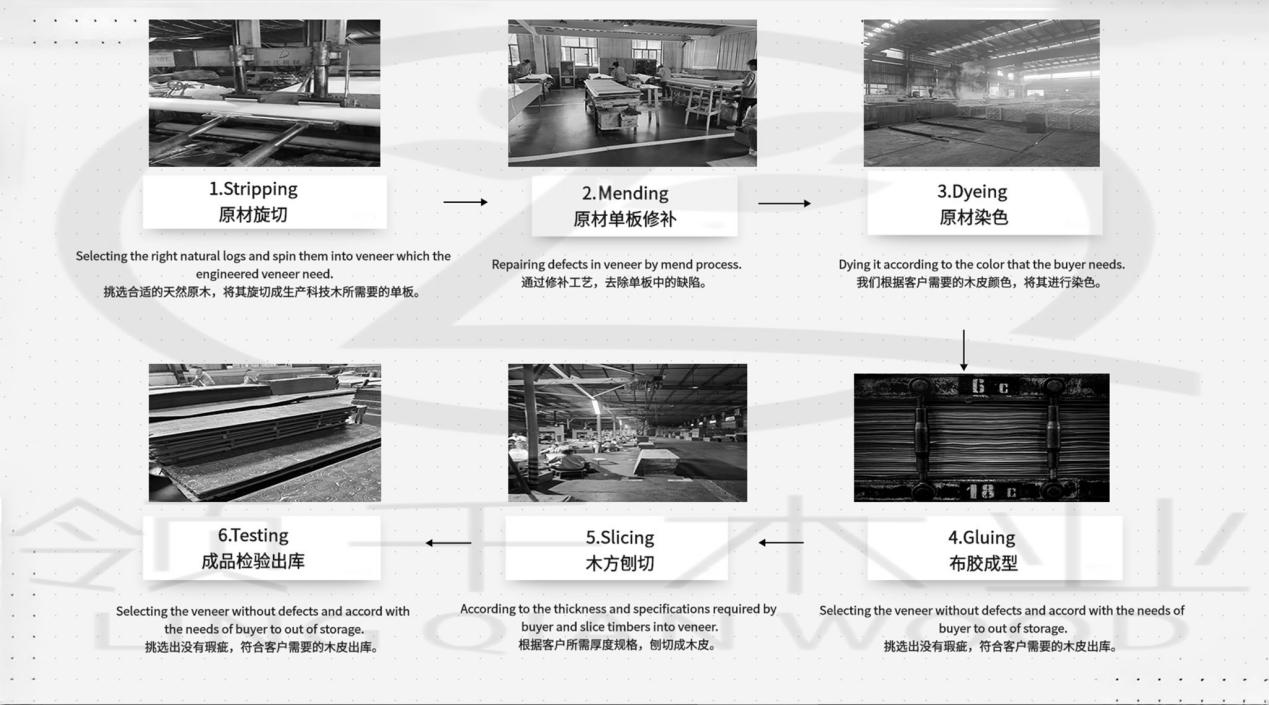

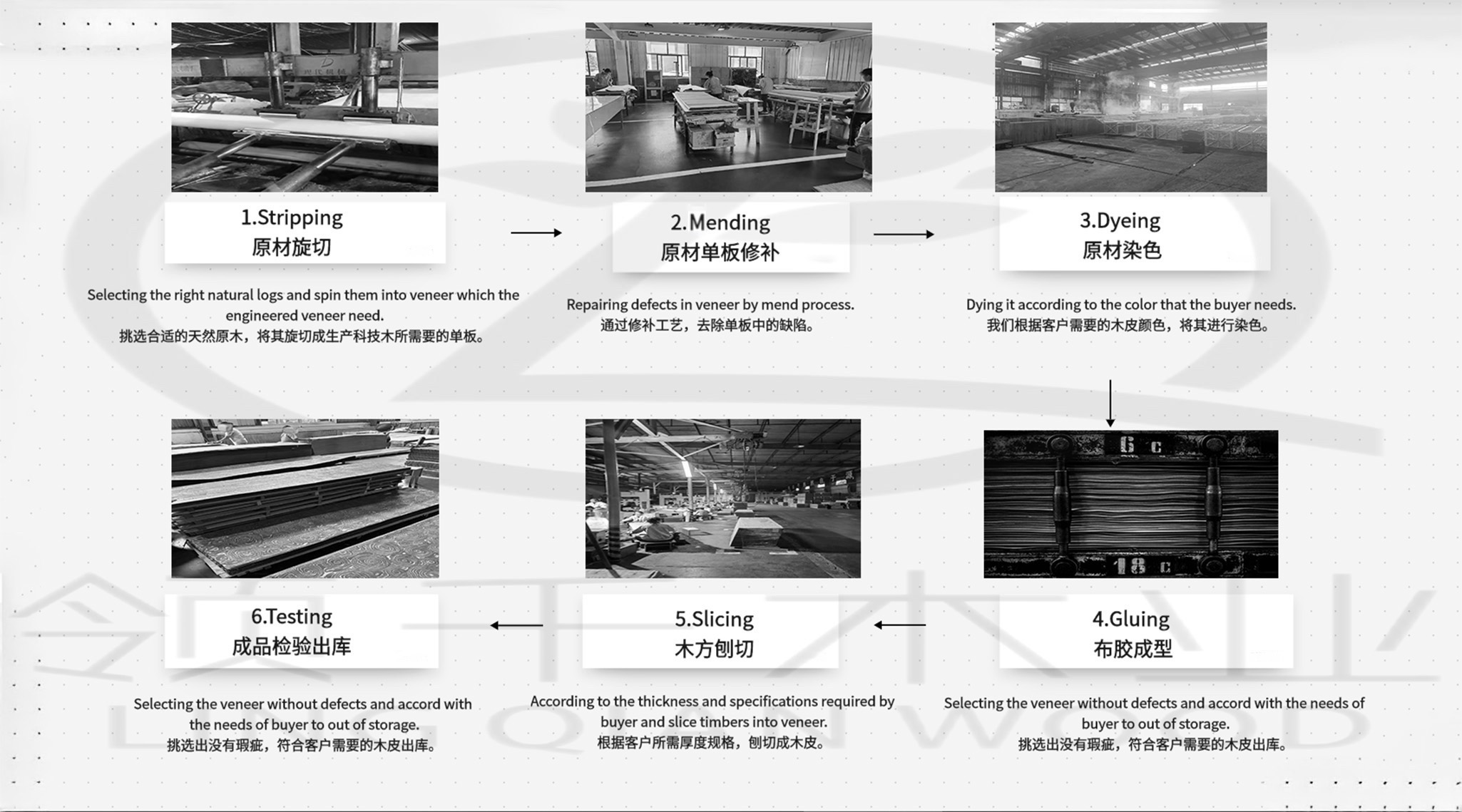

Engineered veneer:

First of all, selecting the right natural logs and spin them into veneer which the engineered veneer need. Secondly, repairing defects in veneer by mend process.Thirdly, dying it according to the color that the buyer needs. Fourthly, According to the buyer needs of the patterns to produce by the specific process. Fifthly, according to the thickness and specifications required by buyer and slice timbers into veneer. Finally, Selecting the veneer without defects and accord with the needs of buyer to out of storage.

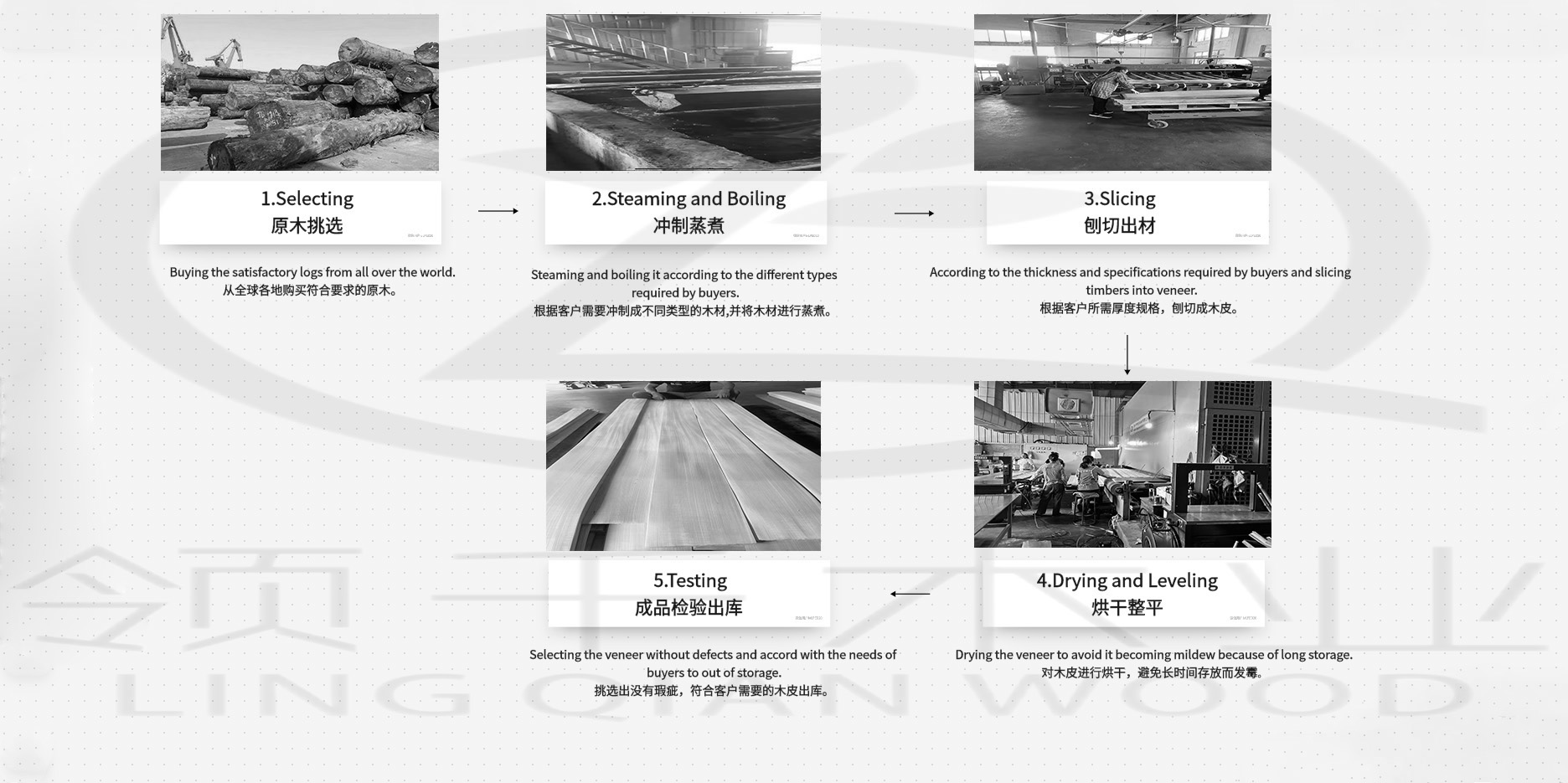

Natural veneer:

First of all, buying the satisfactory logs from all over the world. Secondly, steaming and boiling it according to the different types required by buyers. Thirdly,according to the thickness and specifications required by buyers and slicing timbers into veneer. Fourthly, drying the veneer to avoid it becoming mildew because of long storage. Finally, selecting the veneer without defects and accord with the needs of buyers to out of storage.